Safety management around forkifts

Noccela UWB RTLS solution was offered for forklift collision avoidance and for ensuring safety around dangerous utilities. The main services the solution offers in this use case are peer-to-peer proximity measurements of tracking devices and detection of devices under predefined zones. Both serve the purpose of occupational safety with safety warnings to

- forklift operators

- personnel too close to dangerous utilities

- lone-worker detection

- restricted entries to dangerous zones.

Customer CHALLENGES

One of the main categories of workplace accidents is related to man-machine proximity. Forklifts are responsible for a considerable part of the incidents and the severity of injuries goes up to death. Besides the human and operational impact, the costs for worker compensation and liability insurances for internal logistics activities are increasing year after year

Man-down incidents resulting from slips, trips, and falls consistently account for a large part of all workplace accidents. Especially in lone-worker situations, preventive action can almost eliminate the occurrence of unfortunate incidents.

SOLUTION

Konecranes Hyvinkää site is already equipped with Noccela’s Safety Management Solution for social distancing and contact tracing, which already sets up the infrastructure for further occupational safety features. The ID badges of forklift drivers and the other employees are differentiated in the cloud and alerting of the badges is activated with continuous beeping and LED blinking when employees are closer to the operational forklift than the distance predefined in the cloud. A similar feature was implemented for safety around test benches of high voltage, by attaching an asset tracking tag on it.

The beacons are installed in identified danger zones, to count the number of employees in the zone and to send a text message to the supervisors’ mobile phone in case the number of employees is 1, indicating lone-worker in the specific danger zone. The restricted zones for only authorized employees are triggered to generate beeping and LED and to send text messages to the area responsible, when the unauthorized enters the zones. The differentiating of the authorized and unauthorized badges to multiple zones

is done in the cloud.

TECHNOLOGICAL SOLUTION

Noccela solution called HPR (High-Performance Ranging) is the newest technology providing features from two already known technologies, TDoA (Time Difference of Arrival) and TWR (Two Way Ranging). HPR is using patented technology to provide the ability to use TWR-based tags with almost limitless capacity. HPR is also known and appreciated for its capability to provide the largest coverage for beacons, meaning fewer beacons, fewer cables, and fewer devices to install.

In this case, the technology works, so the proximity measurements gain the accuracy of centimeter-level, which is considered a measure of the reliability of the safety solution. The independent mode of beacons that were adequate to serve the purpose of head counts under their coverage is also one of the most cost-effective solutions of similar kind that Noccela can uniquely provide.

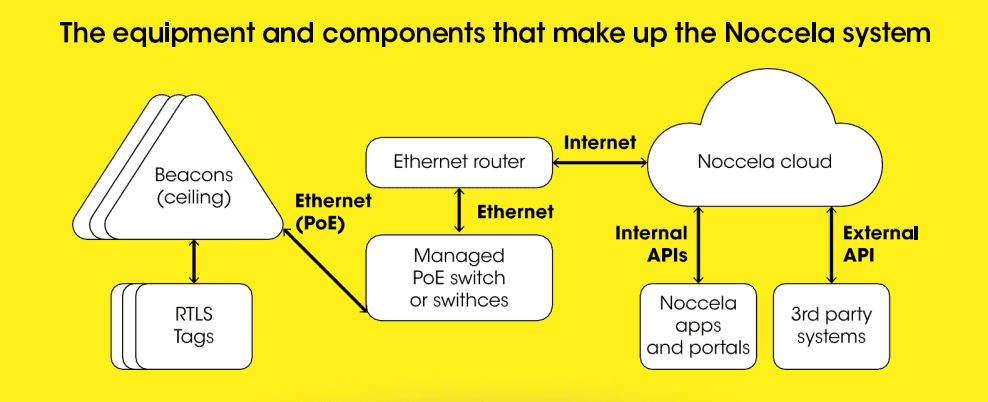

Overall, the solution works with cloud supported engine, whereas the tags are sending the positioning information to beacons, which send the information to the cloud, where the actual calculation is happening and restored for analysis and reports via third-party API.

BENEFITS

- Forklift operators and employees nearby gain increased awareness of each other, to act carefully.

- The information on the zones where forklifts are mostly active could be used for danger zone detection and definition.

- Raising awareness of the danger zones and restricted areas helps avoid collisions as well as accidents caused when unauthorized employees try to pick up inventory from the warehouses.

- Lone-worker RTLS alert sent to supervisors fosters their job to ensure the workers

are safe even while working alone in dangerous areas and one can call for immediate help in case of emergency. - Reduction of accidents in the workplace, reduction of severity of injuries, increased credits as a safer place to work, reduced costs for worker compensation and liability insurances for internal logistics activities.

COMPANIES INVOLVED

Konecranes Oyj is a Finnish company, headquartered in Hyvinkää, which specializes in the manufacture and service of cranes and lifting equipment. Konecranes products are made for industries handling heavy loads meaning ports, intermodal terminals, shipyards, and bulk material terminals. Konecranes Industrial Equipment business division offers hoists, cranes, and material handling solutions for e.g. industries in automotive, metal production, waste-to-energy, pulp and paper, and wood processing.

Download brochure