Logistics and Warehouse Management

Noccela UWB RTLS solution was offered to optimize warehouse operations based on RTLS-based facts. The two main services the solution offers are real-time visibility of moving vehicles and pallets and data for analyzing the palette routes that contribute to lead times. Real-time visibility of assets helps the researchers to identify improvement points of the operations and the analytics data enables fact-based optimization of the warehouse layout.

CHALLENGES

- The customer had several times changed the layout of the warehouse in order to meet the competitive service levels that they provide to their customers. The optimization so far took the trial and error approach that always lead to question if the best possible results were achieved.

- Achieving detailed control over the entire 12000 sqm warehouse area is also challenging for the limited number of responsible personnel, as the warehouse is active in the entire area simultaneously.

- Constant movement across vehicle moving area is identified as risky, therefore, optimizing the movement frequency of the forklifts and palette trucks is essential.

- Improving the efficiency of the forklifts and palette trucks is difficult without identifying the instances of their idle times and extensive driving with or without palettes on them. Therefore the customer has less control over operational costs. For instance, the use of palette trailers is an appealing way to move more palettes and reduce the number of rounds a vehicle has driven, but the right instances to use them are unknown.

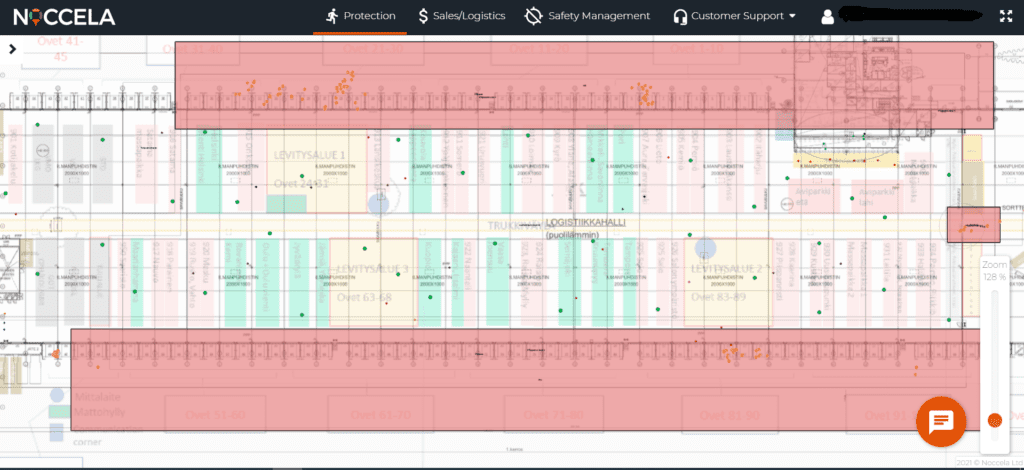

DEPLOYMENT

- The asset tracking tags on moving vehicles and the palettes were differentiated in the cloud to recognize them separately in the system. The type of vehicle is also differentiated according to being a forklift, palette truck, or palette trailer in the cloud.

- The asset tracking tags were attached to the palettes when they arrive from the harbor, to start tracking them. At the end, the tag is removed when the palette is loaded back to be transported to the destination. The restricted areas are geo-fenced in all arrival and departure gates to avoid the tags from leaving the premises and if they do, it is set to beep constantly.

- The routes of all tags are recorded as historical data and heat maps can be generated for analysis purposes. The parameters saved in the cloud include position, travel time, distance, idle time, and idle position.

BENEFITS

- The visibility of the assets in the large warehouse was fully gained due to RTLS enablement, and due to the differentiation of the assets, the numbers of palettes in arrival and departure areas, the palettes on the move, and all the moving vehicles are known and counted remotely.

- The differentiation of forklifts and palette trucks is mainly used to calculate the utilization of each type by tracking their movement times with and without palettes and facilitating the comparison of the data. The ability to Identify the situations where a palette trailer could be used instead of forklifts or palette trucks, gave that more control over the costs, by improving the utilization % of the vehicles.

- The total tracking time of palettes is similar to the warehousing time. Information such as how long the palettes spend in the warehouse if they follow the first in first out rule under their service levels, or if they retain unnecessarily in the warehouse could be easily detected.

- The optimization of the warehouse layout and routes could be executed based on facts and the improvements could be measured using the simplest KPI of the time palettes spend in the warehouse. The plan could also be fine-tuned according to the service level requirements of the palettes while maintaining safety measures to avoid a collision.

PARTIES INVOLVED

For more than 140 years, DB Schenker has pushed the limits of the logistics and supply chain management industry. They provide thousands of products for customers who are focused on finding the best shipping solution. DB Schenker combines all transport and logistic activities, employing over 72000 staff spread across about 2,000 locations in about 140 countries.

The logistics center situated in Lieto Finland receives and warehouses the palette shipments from abroad to distribute to their destinations in Finland after sorting them according to the destinated city.

TUAS has the mission to train professionals with an emphasis on labor market needs and conduct research and development which supports instruction and promotes regional development in particular. The education in UAS emphasizes cooperation with the business, industry, and service sectors at the regional level in particular. TUAS research, development, and innovation (RDI) activities combine the creative and innovative ideas of students, the teachers’ expertise, and the experience of project professionals.

Download brochure