World’s largest digitalization of wood processing factory

Noccela UWB RTLS solution was offered for enhancing factory automation. The two main services the solution offers are digitalizing operational information and providing data for analytics for the sole benefit of improving operational efficiency of the manufacturing floor. Digitalizing stock information leads the customer save time and costs whilst the analytics data provides the customer the ability to make fact-based decisions to optimize resources.

Customer CHALLENGES

- Keeping track of the wood panel stock: The counts, and categories based on their properties.

- Managing supply to manufacturing and processes needs personnel involvement.

- Forklift operators spend time keeping track of stock.

- Forklift operators spend time searching for the location of requested material in work orders.

- Operational expenses of forklifts are high; hence optimization is crucial. Frequent forklift operations on the manufacturing floor call for safety measures.

REQUIREMENTS

- Positioning in real time providing x, y, and z coordinates

- Tracking details differentiated between wood panel pallets and the forklifts that carry them.

- The properties of the wood panels mapped with tracking device IDs of the palettes that carry them.

- Time taken for forklifts to complete certain workflows.

- Time the forklifts move without pallets.

- The counts of the pallets in stock, and manufacturing floor near machine areas.

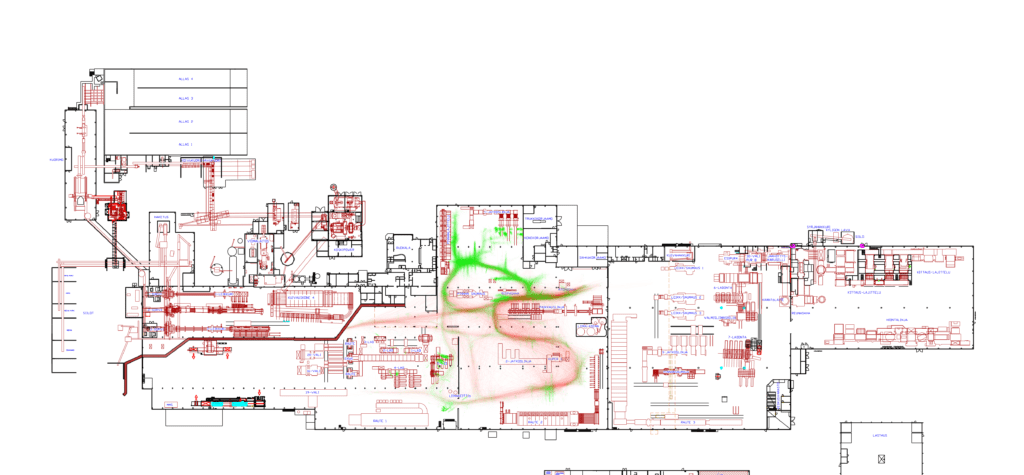

- Workflow and heatmap visualization.

RTLS DEPLOYMENT

- 25000 sqm manufacturing and stockpiling floor.

- Accuracy 0,5-3 m.

- 160 beacons.

The manufacturing floor is a special case of system installation challenges that Noccela engineering team was excited to overcome by

- Identifying specifics of the challenges using new tools for analyzing and troubleshooting.

- Beacon amounts adjusted to area-specific accuracy requirements.

BENEFITS

- The information on the properties of the wood panels becomes digitally known, with their location information, so the paperless work orders sent to forklifts could be more instructive with the location information to avoid time wasted on searching for the right pallets.

- The timely supply of the panels to relevant machines avoids waiting times, as well as timely restocking of the processed to avoid unnecessary cluttering on the manufacturing floor.

- The utilization % of the forklifts becomes measurable in order to improve efficiency.

- The routes of the forklifts could be used to avoid collision and optimize the routes.

- Identification of busy/dangerous zone detection to optimize area utilization.

- New information generation of the vertical position of panel palettes in the stockpile.

Continuous improvement of our operations is in the core of Koskisen values. One area of improvement we had was identifying different veneer bundles for more efficient inventory management. Noccela system can locate and identify our products under progress precisely. The whole solution has been easy to implement and may provide us more value than we ever thought!

ICT Manager at Koskisen Oy, Teemu Similä

PARTIES INVOLVED

DNA Oyj (DNA Plc) is a Finnish telecommunications group that provides voice, data, and TV services. DNA is an expert in straightforward solutions and the use of smart and innovative technologies. Its mission is to provide products and services that make its customers’ lives easier. Technology is just a tool. Expertise, passion, and the ability to harness technology to help and entertain – is what DNA is about.

Koskisen Oy is a family company that processes Finnish wood into products that stand the test of time. Over the decades, the company has evolved into an international wood products and processing expert. The company’s aim is to always exceed their customers’ expectations and is quite experienced about customer requirements set for their wood products, and promotes their customers’ business through innovative product and service solutions.

On the manufacturing floor, the customer processes wood to customized plywood, clipboards, lumber, and thin veneer. The forklifts move to the manufacturing floor to place the wood panels to be processed to relevant machines and stock back the processed panels in the storage area.

Nortal is a multinational technology consulting company that specializes in digital transformation. It offers services such as strategic consulting, software development, data analytics, and cybersecurity. Nortal helps businesses and government organizations navigate complex digital challenges and implement innovative technology solutions.

Download brochure