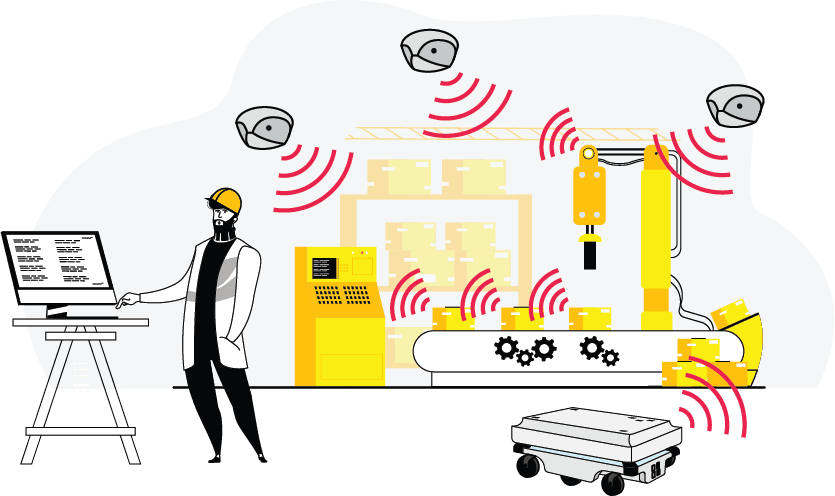

Smart Factories

Industrial sites are on a quest for automation and digitalization and you can speed up this transformation with Noccela’s s RTLS technology and expertise. While a lot is being talked about Smart Factory, Industry 4.0, and LEAN processes, it may be difficult to determine how to best get started with digitalizing operations. The solution is easy to deploy with one or two functions and expand on the way as the vision matures. Commonly used starting points of our customers have been forklift tracking, automated (paperless) work orders, first-in-first-out automation, and logistical challenges of tracking assets.

Lean Production

Optimize Lean Production with UWB-Powered Digitalization

Transform your factory floor by digitizing workflows with real-time, rule-driven location intelligence. Reduce waste, eliminate bottlenecks, and automate processes for seamless efficiency.

Visibility and Monitoring

- Track products, assets & staff in real time for full operational transparency.

- Monitor production flows to pinpoint delays and supply chain bottlenecks.

Efficiency and Consistency

- Minimize assembly line pauses with automated digital Andon alerts.

- Cut shrinkage by tracking high-value tools and inventory.

- Shorten lead times with dynamic digital work orders.

- Ensure manufacturing consistency through location-verified processes.

Speed and Automation

- Find inventory instantly—no more manual searches.

- Auto-calculate production status for real-time progress updates.

Logistics and Warehouse

Transform Warehouse Logistics with UWB Precision Tracking

Knowing the exact location of pallets and packages unlocks tremendous benefits for logistics centers. Goods are no longer lost for days, and tracing investigations become effortless. Optimize warehouse operations to improve delivery lead times and elevate service quality.

Tracking and Optimization

- Track every asset across your facility map in real-time

- Generate productivity KPIs (forklift utilization, pallet turnover)

- Optimize warehouse layouts with data-driven insights

Speed and Efficiency

- Eliminate bottlenecks with instant congestion alerts

- Automate FIFO workflows to prevent stock aging

- Slash tracking costs by monitoring only moving vehicles

Safety and Automation

- Enforce forklift safety with dynamic danger zones

- Reduce manual searches for misplaced pallets

Occupational Safety

Preventing Workplace Accidents with UWB

One of the main categories of workplace accidents is related to man-to-machine proximity. Forklifts and dangerous industrial utilities account for severe incidents – including fatalities. Beyond human costs, compensatory expenses continue rising. Proactive prevention reduces risks, enhances safety, and improves ROI.

Real-Time Monitoring

- Enable tracking of workers, dangerous assets, and utilities for safety

- Define dynamic/fixed danger zones around moving or stationary hazards

- Alert workers if they enter danger zones

Proactive Alerts

- Alert operators when other workers approach dangerous equipment

- Automatically detect and assist lone-workers requiring help

Emergency & Analytics

- Enable smart evacuation for real-time visibility of evacuation flow

- Automate roll-calling at muster stations

- Generate Safety KPIs to measure progress and improve practices