Logistics and Warehouse Management

Noccela’s UWB RTLS was deployed to optimize warehouse operations with Industry 4.0 Digital Integration, providing real-time Inventory in Transit Visibility of moving vehicles and pallets, along with detailed analytics on pallet routes that affect lead times. This visibility allows the customer to eliminate Operational Inefficiencies, and the historical route data enables fact-based layout improvements, enhancing Material Flow Efficiency and supporting Process Reliability & Stability.

Customer Challenges

- The customer had repeatedly changed the warehouse layout to maintain service-level competitiveness, but previous changes relied on trial and error.

- Managing a 14,500 m² high-velocity warehouse was difficult for limited staff, as activity occurs everywhere simultaneously, reducing visibility and slowing decisions.

- Frequent movement in shared forklift and pallet truck aisles introduces risk, making routing optimization essential for stable operations.

- Fleet efficiency was difficult to evaluate without identifying idle time, unnecessary driving, or opportunities to use pallet trailers more effectively, reducing cost control and generating Operational Inefficiencies.

Requirements

- Asset tracking tags on vehicles and pallets were differentiated in the cloud by identity and vehicle type (forklift, pallet truck, trailer), enabling granular Inventory in Transit Visibility and seamless Industry 4.0 Digital Integration.

- Pallets were tagged at harbor arrival and monitored until outbound loading. Geofenced arrival and departure gates prevented tags from exiting the premises, supporting process stability.

- Historical route mapping and heatmaps recorded position, distance, speed, idle time, and dwell time; feeding KPIs for Material Flow Efficiency and Forklift Efficiency.

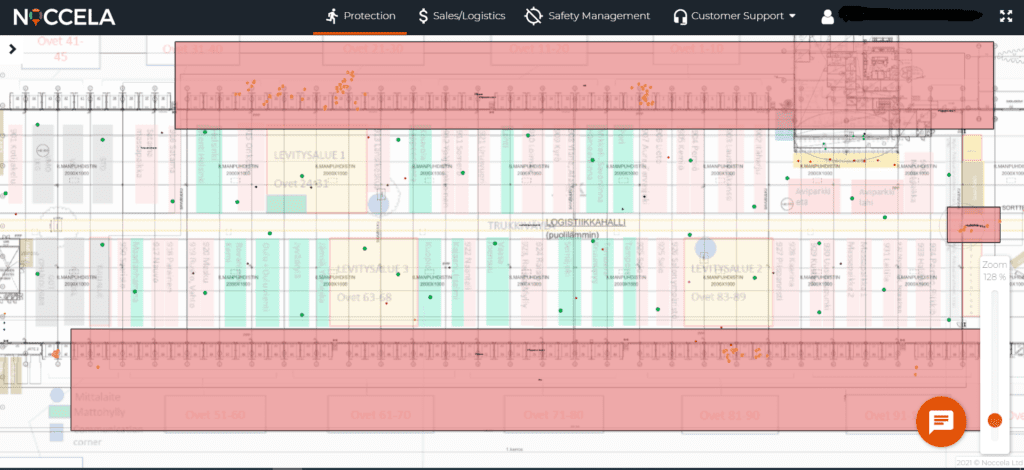

Installation visualization of 36 beacons in 12000 sqm.

Detailed Benefits and Cost Savings

- Complete Inventory in Transit Visibility Across All Warehouse Zones

RTLS provided full visibility of pallet and vehicle flows, eliminating search time and enabling remote tracking of pallet positions across arrival, departure, and active movement zones.

Formula: Visibility Savings = (Search minutes avoided per pallet × pallets/year × operator cost/min)

Example Calculation: 3 × 500,000 × 0.50 = €750,000/year

- Improved Forklift, Pallet Truck & Trailer Utilization

Vehicle-type differentiation revealed nonproductive movement, identified opportunities to use pallet trailers, and improved fleet utilization across forklifts, pallet trucks, and trailers.

Formula: Vehicle Utilization Savings = (Non productive driving minutes reduced/mission × missions/year × vehicle cost/min)

Example Calculation: 1.5 × 150,000 × 0.60 = €135,000/year

- FIFO Break Detection & Excess Retention Reduction

Tracking reveals exact dwell times, FIFO violations, and unnecessary retention, ensuring pallets follow required service-level timelines and reducing inefficient stock aging.

Formula: FIFO Delay Avoidance = (Delay hours avoided/year × throughput value/hour)

Example Calculation: 0.1 × 25,000 × 700 = €1,750,000/year (Retention avoided: 0.1 h/pallet, Affects ~5% of pallets → 25,000 pallets/year)

- Fact-Based Layout Optimization & Route Improvements

Using RTLS-generated heatmaps and route data, layout optimization reduced congestion and travel distance while maintaining safety and supporting Process Reliability & Stability.

Formula: Route Optimization Savings = (Seconds saved per pallet movement × movements/year × labor or equipment cost/sec)

Example Calculation: 15 × 500,000 × 0.009 = €67,500/year

| Benefit Area | Primary Cost Driver | Example Annual Savings |

|---|---|---|

| Inventory in Transit Visibility | Search inefficiency removed across ~500,000 pallets/year | €650,000–€800,000/year |

| Vehicle Utilization (Forklifts, Pallet Trucks, Trailers) | Reduced empty driving & idle time across ~150,000 missions/year | €110,000–€150,000/year |

| FIFO / Retention Optimization | Avoided excess dwell-time for high value pallet flows | €1.5M–€1.9M/year |

| Route Optimization & Congestion Reduction | Seconds saved per pallet movement across entire 14,500 m² facility | €55,000–€75,000/year |

| Safety Driven Route Stability (Collision Avoidance) | Reduced disruptions, damage, admin time | €25,000–€60,000/year |

| Cycle Counting & Inventory Accuracy Gains | Fewer misplacements + automated stock confirmations | €40,000–€80,000/year |

Our cooperative company advised us to take Noccela into our project of Baltic Loop, which was focusing on improving efficiency on indoor logistic.

Noccela performed a quick installation for the terminal area of 12.000 m2. The accuracy of Noccela’s solution was perfect, and the whole cooperation with them went smoothly and effectively. Noccela came up with innovative ideas of their own, and the engineering team performed rapidly and accurately all our wishes and requirements related to the project.

Kari Lindström, Lecturer, Turku University of Applied Sciences, Logistics, Services and Production Economy

Academic References used in this article

- Acta Mechanica Slovaca (2024) – Literature review of RTLS in manufacturing & logistics.

- Sensors (2022) – UWB RTLS design, TDoA algorithms, EKF stability in complex industrial environments.

Parties Involved

For more than 140 years, DB Schenker has pushed the limits of the logistics and supply chain management industry. They provide thousands of products for customers who are focused on finding the best shipping solution. DB Schenker combines all transport and logistic activities, employing over 72000 staff spread across about 2,000 locations in about 140 countries.

The logistics center situated in Lieto Finland receives and warehouses the palette shipments from abroad to distribute to their destinations in Finland after sorting them according to the destinated city.

TUAS has the mission to train professionals with an emphasis on labor market needs and conduct research and development which supports instruction and promotes regional development in particular. The education in UAS emphasizes cooperation with the business, industry, and service sectors at the regional level in particular. TUAS research, development, and innovation (RDI) activities combine the creative and innovative ideas of students, the teachers’ expertise, and the experience of project professionals.